Plan AdvantagesPlan Advantages

-

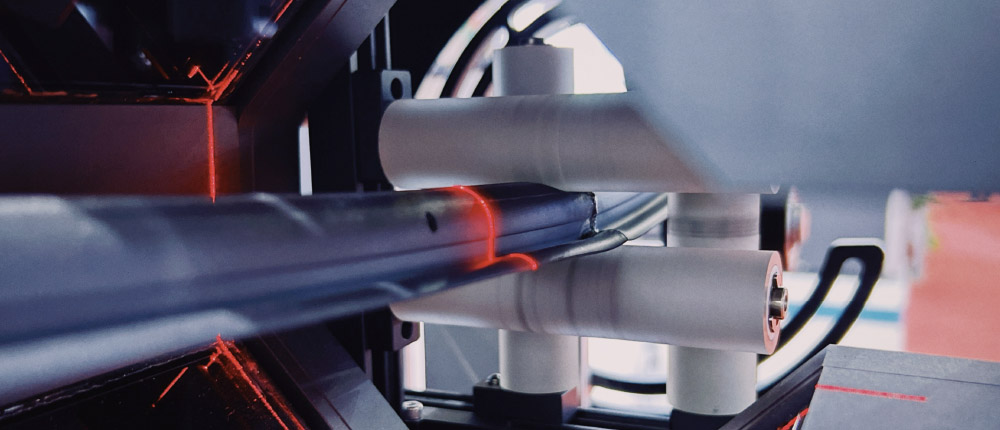

Standardized measurement devices are used in all production stages

-

Supporting customization from inspection logic to software and structural design

-

New products are constantly being developed

Semi-finished product section

- Splice Check

- Bead Filler Inspection

- Tread Width Measurement

- Zero-degree Cap Ply Measurement

- Bead Roundness Inspection

- Rubber Cutting Angle Measurement

- Cutting Defect Inspection

- Inner liner Thickness Measurement

- Quiet Tire Adhesive Coating Inspection

- X-ray Wire Density Inspection

- Vulcanization Mold Character Inspection

- Tire Exterior Inspection

- Uniformity Measurement

WhatsApp

WhatsApp Follow Us

Follow Us