Industry Challenges and Needs

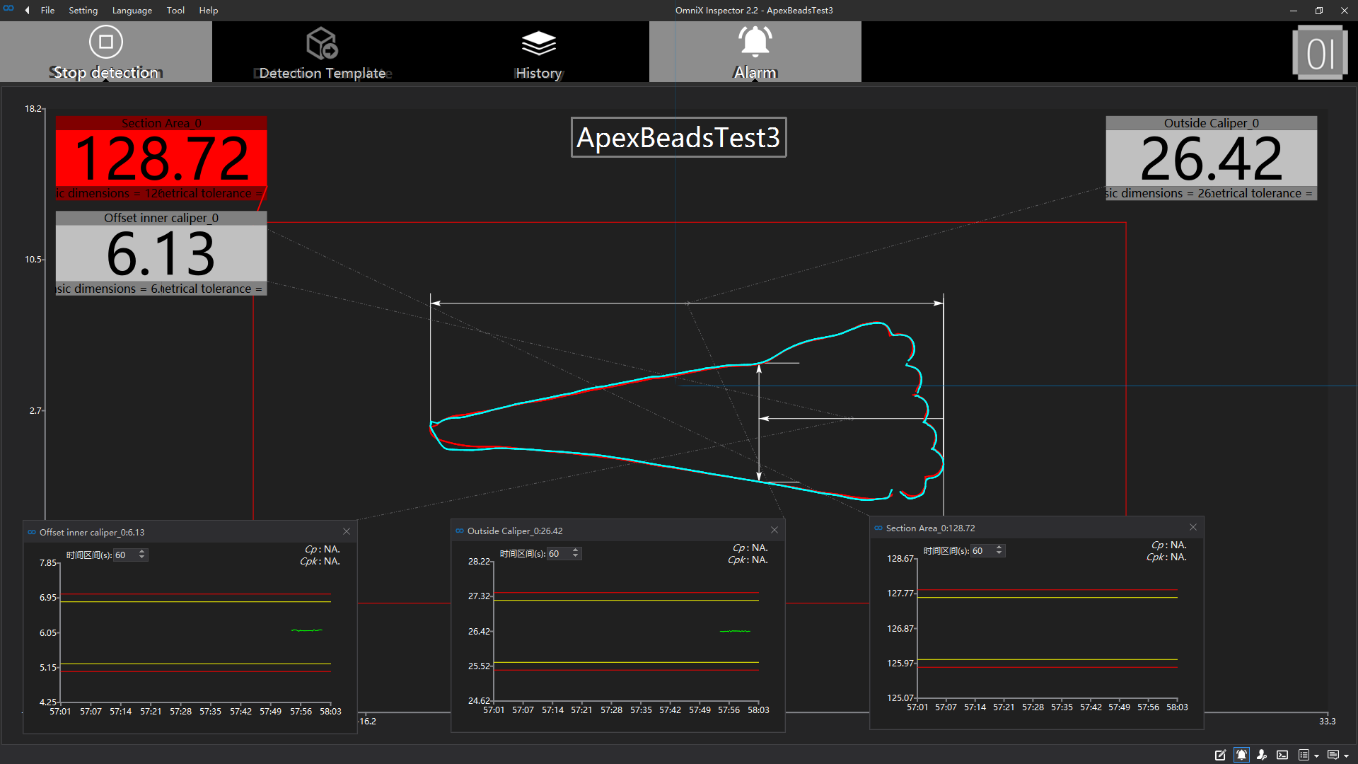

The triangular rubber strip in the bead area is a key filler in tires, supporting the sidewall and providing a smooth transition, enhancing driving stability, steering, and comfort. As a filler material above the steel bead, the triangular rubber plays a crucial role in cushioning impacts and preventing air ingress during molding. Even minor dimensional changes can compromise the seal between the triangular rubber and the steel bead, significantly affecting the quality and lifespan of the finished tire, as well as reducing comfort during driving.

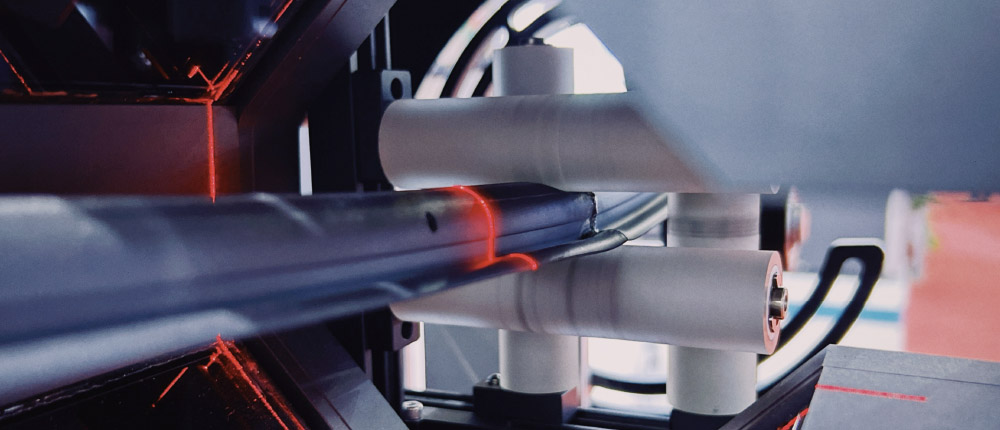

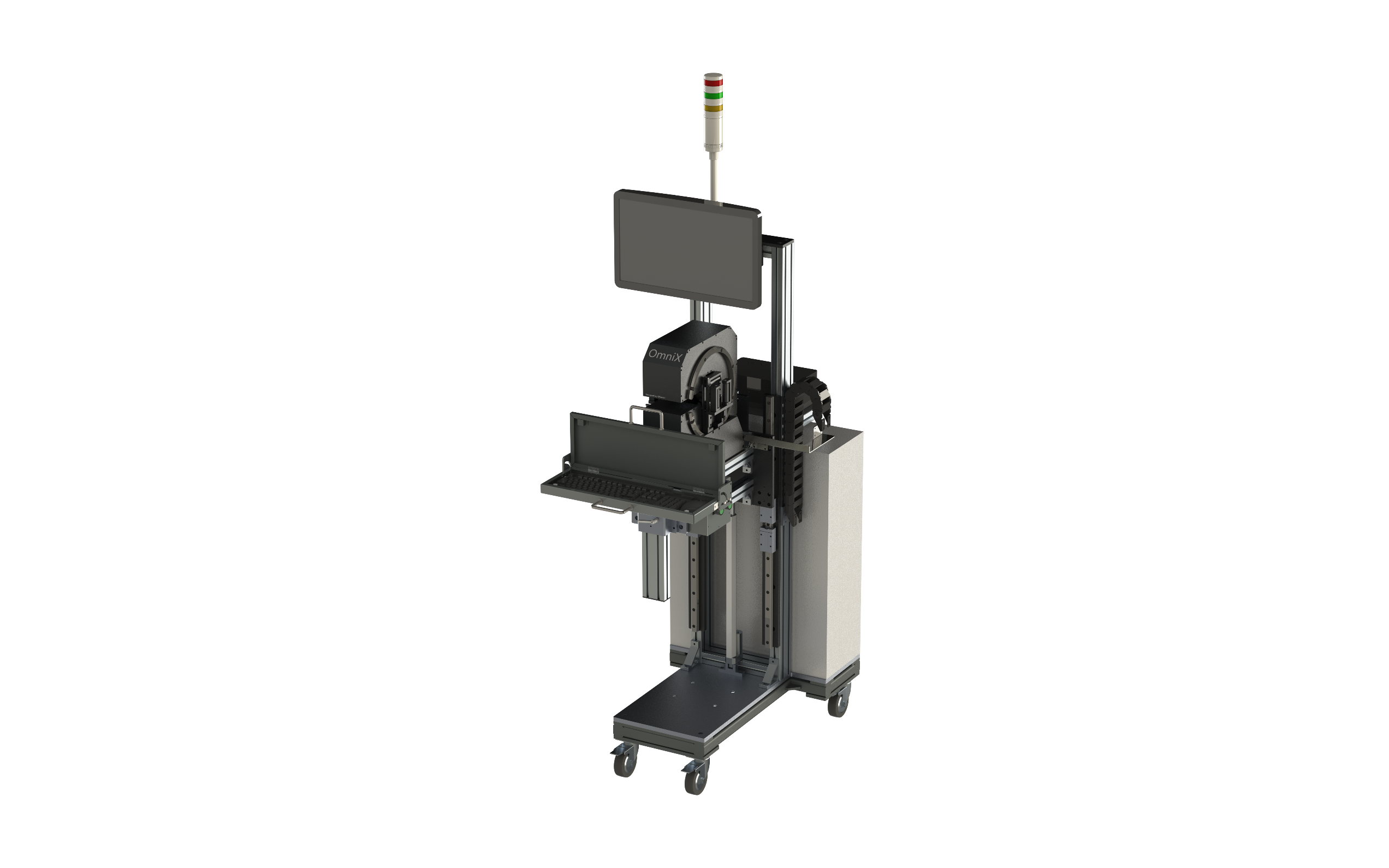

The Omni series, developed specifically for objects with strong light absorption, irregular shapes, and variable thickness, overcomes the limitations of traditional 2D vision inspection. It operates independently of lighting conditions and material properties, enabling efficient and precise continuous monitoring of the triangular rubber.Based on the principle of laser triangulation, the Omni series employs multiple sensors and line lasers to form an optical measurement module that provides real-time, multi-angle accurate measurements of the object. Through specialized algorithms, it merges sectional profiles captured by each sensor into a complete profile, achieving precise online measurement of surface contours and detecting minute defects.

WhatsApp

WhatsApp Follow Us

Follow Us