With the rapid development of China's rail transit, the operational history of rail transportation is continuously expanding, along with an increasing demand for passenger and freight services. This growth necessitates higher standards for the operational safety and routine maintenance of rail transit facilities and equipment. The advent of 3D line laser technology has brought a comprehensive technological innovation to the rail transit industry, enabling users to effectively meet the detection challenges in high-speed scenarios and providing strong support for the operation and maintenance (O&M) of rail transit.

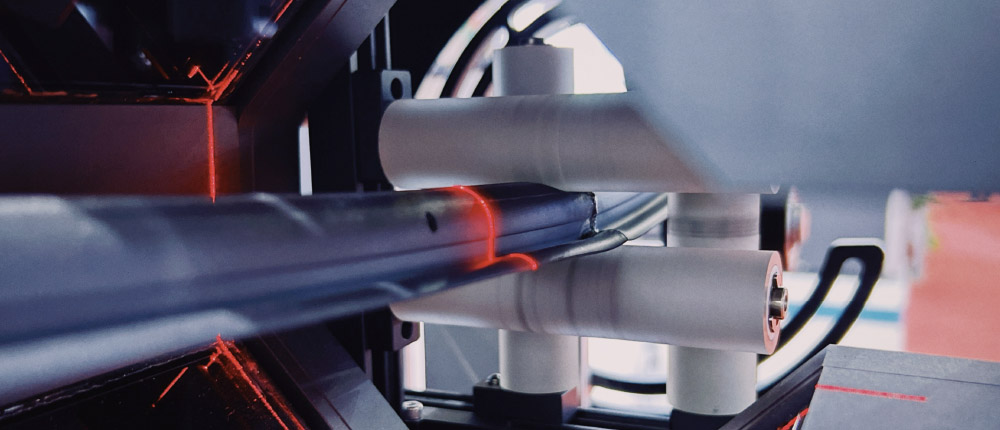

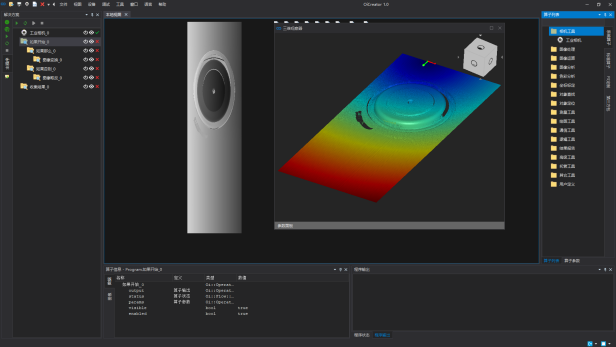

Now, utilizing the GTC series split cameras developed specifically for high-speed detection scenarios, in combination with the Oi-Smart Vision universal software platform, it's possible to perform high-frame-rate contour scanning of trains in motion. Leveraging ultra-fast image processing speeds and powerful image processing algorithms, these contours are merged into detailed 3D images. This enables precise measurement of key dimensions and defect inspection for trains and their components. This non-contact online detection solution significantly improves detection efficiency and generates a vast amount of inspection data. It allows for real-time monitoring of critical dimension data, helping users promptly identify issues like wear, cracks, and missing parts. This significantly enhances production safety, automates equipment O&M, ensures work quality, improves the efficiency of equipment production and maintenance decision-making, and promotes rail operation safety.

WhatsApp

WhatsApp Follow Us

Follow Us