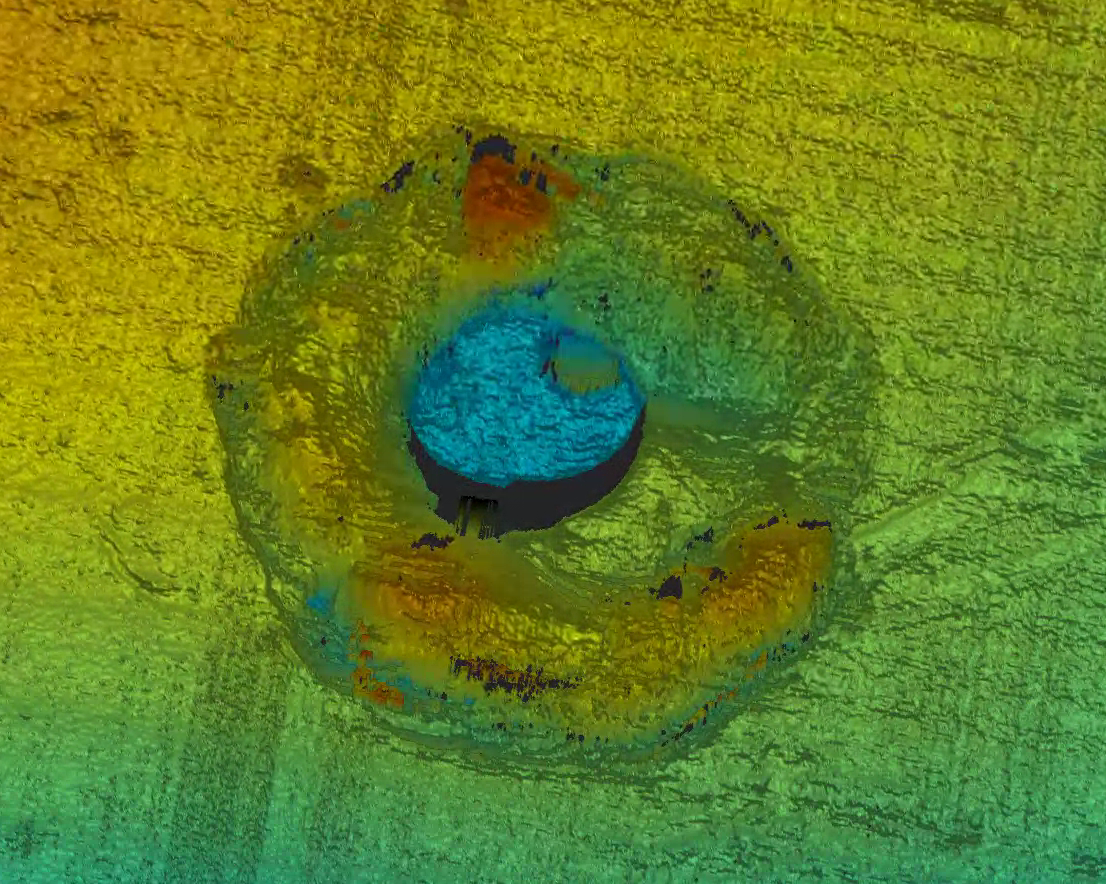

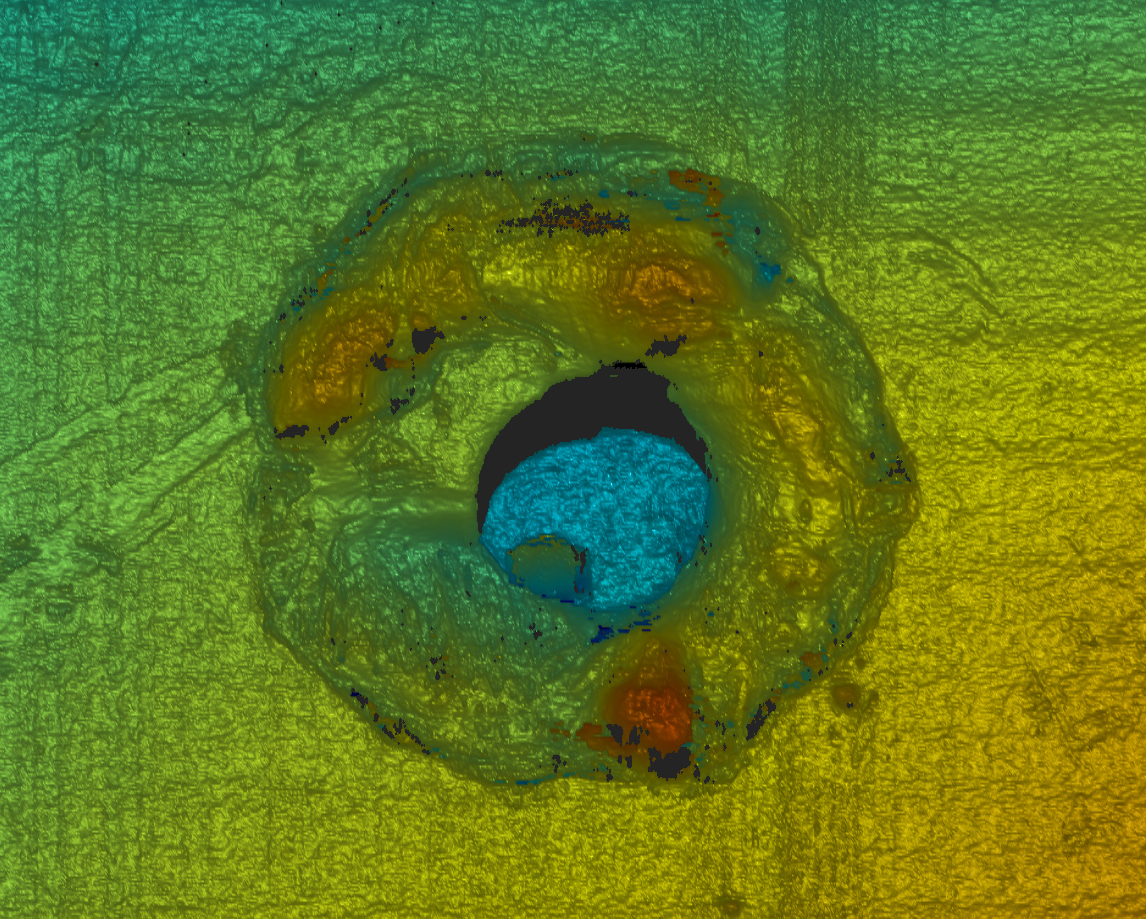

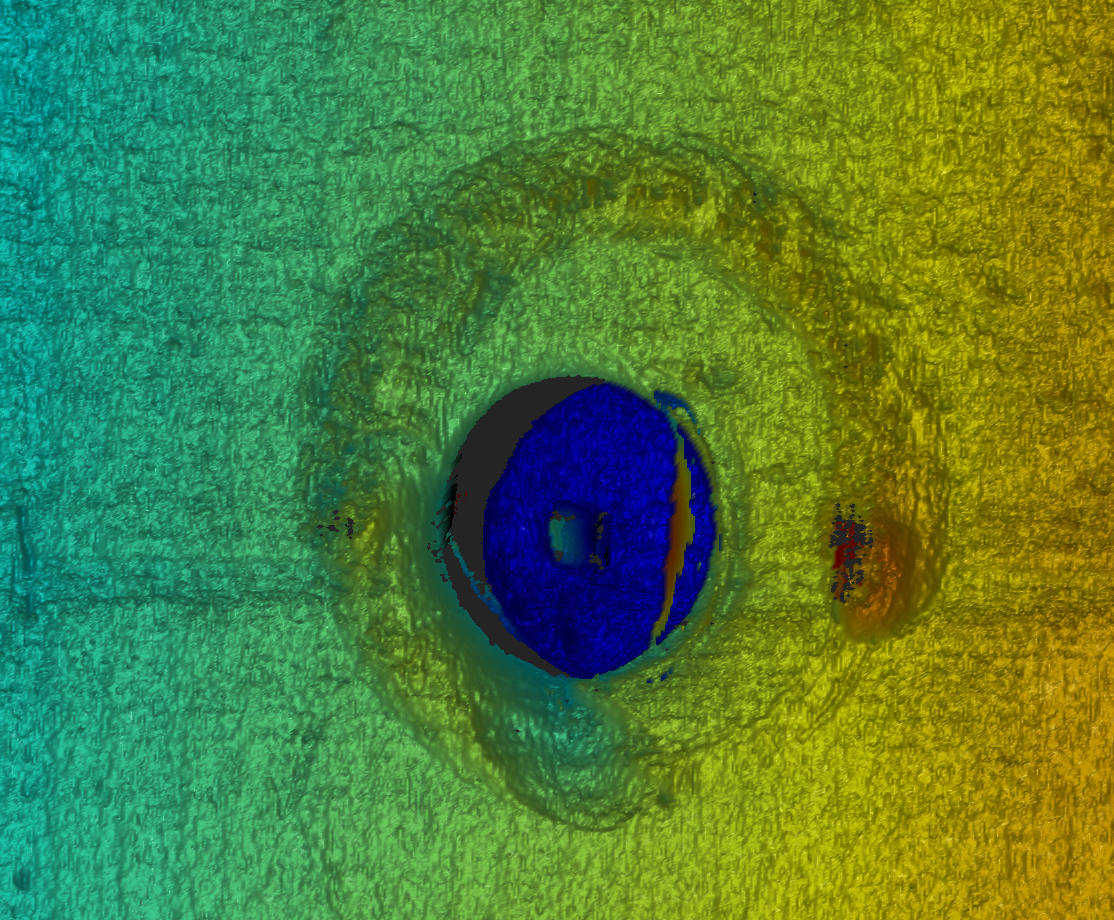

Due to the uniqueness of power batteries, quality issues such as battery swelling, leakage, and fire can lead to exceptionally severe consequences. Therefore, the expansion and upgrading of the industry, along with the application of new materials and new technologies, mean that the manufacturing process of power batteries requires more refined and stringent quality control. Now, 3D vision inspection technology can be introduced at various stages of product manufacturing, helping enterprises accurately identify minor defects, improve inspection efficiency, and product yield.

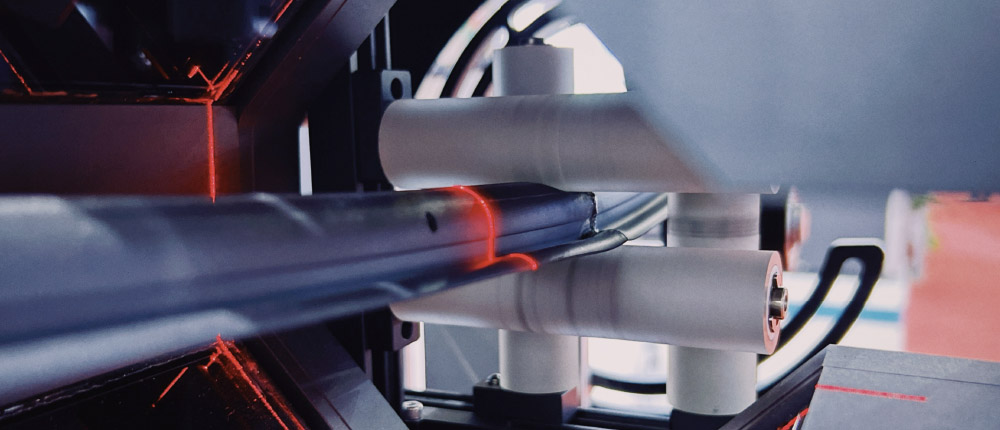

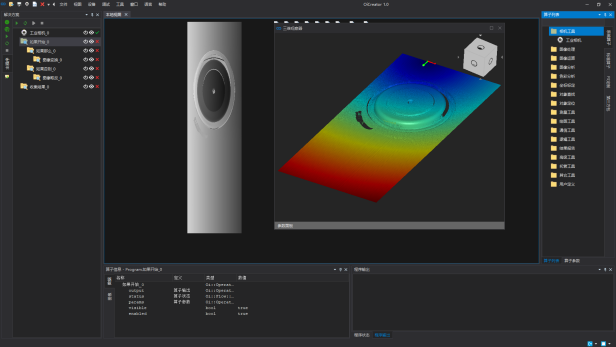

Leveraging the high-performance GTS series 3D laser profiling distance meters, combined with advanced image processing algorithms and measurement and inspection algorithms provided by Oi-Smart Vision, high-quality 3D point cloud images are obtained. Coupled with 2D vision inspection, it meets the fast-paced, high-precision demands for defect detection and precise measurement in different stages of lithium battery production, including presence/absence detection, various defect detections, critical dimensions, flatness, thickness measurements, etc., providing tangible assurance for product quality control.

WhatsApp

WhatsApp Follow Us

Follow Us