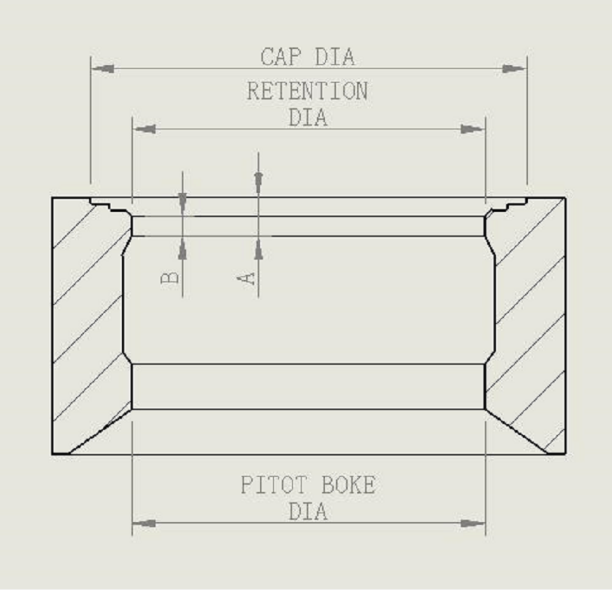

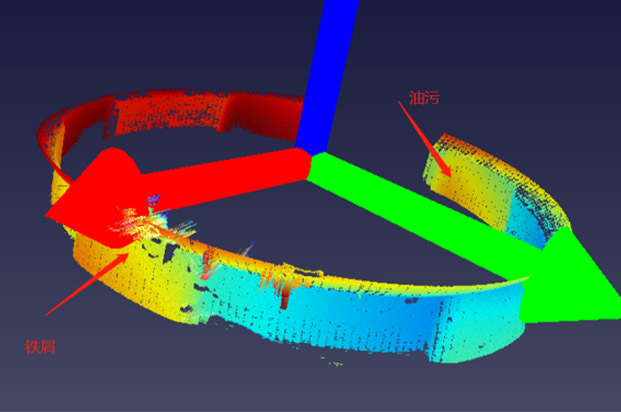

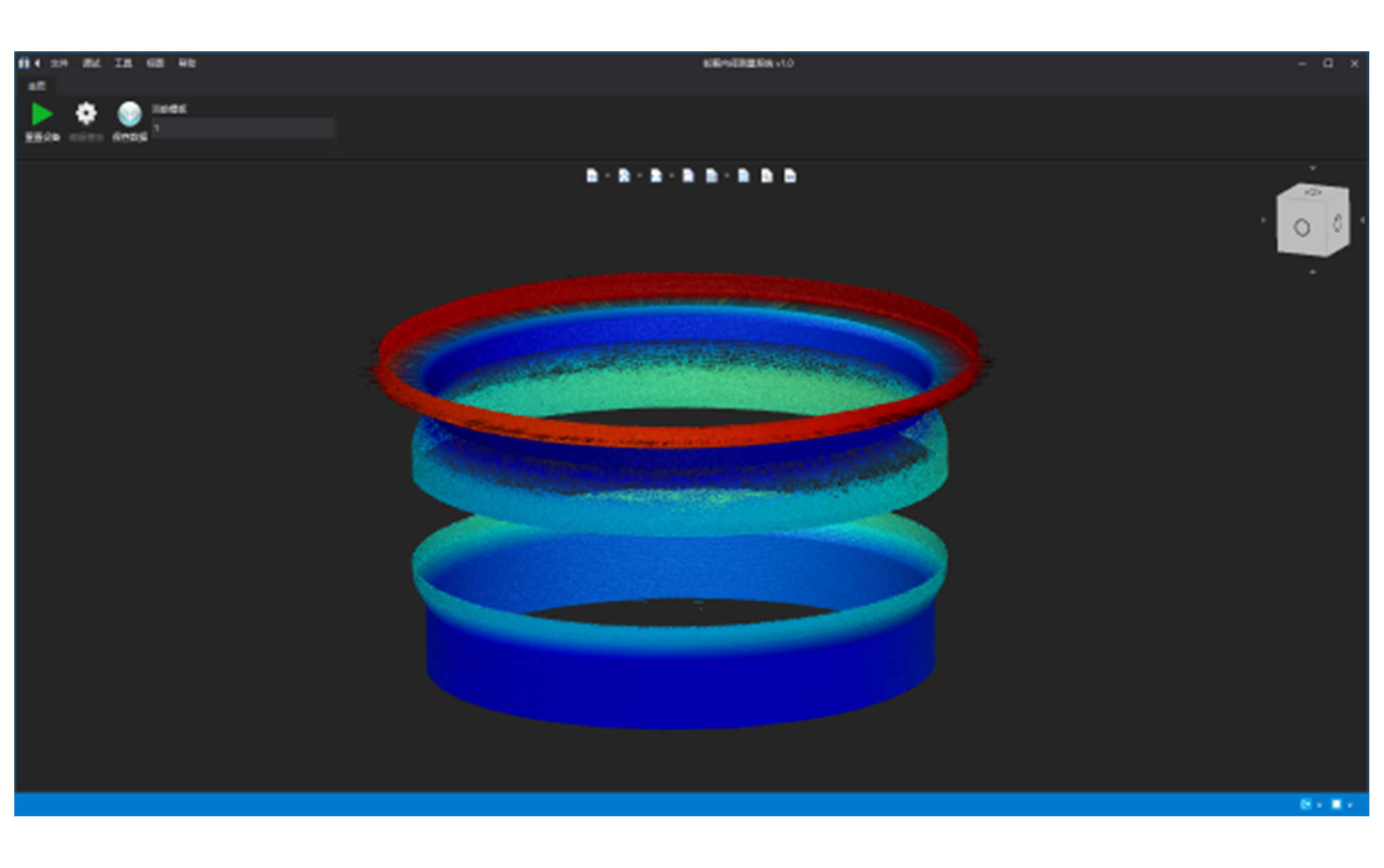

The hub's center hole is the connection point between the hub and the axle, where the processing diameter and roundness directly affect whether the wheel's geometric center can align with the hub's geometric center, playing a crucial role in the vehicle's stability and safety. In hub production, the small and deep nature of the center hole, along with limited space and the tendency for residues like coolant and metal shavings to remain after CNC machining, presents significant challenges for precise measurement. Current inspection solutions struggle to efficiently and accurately measure these critical dimensions.

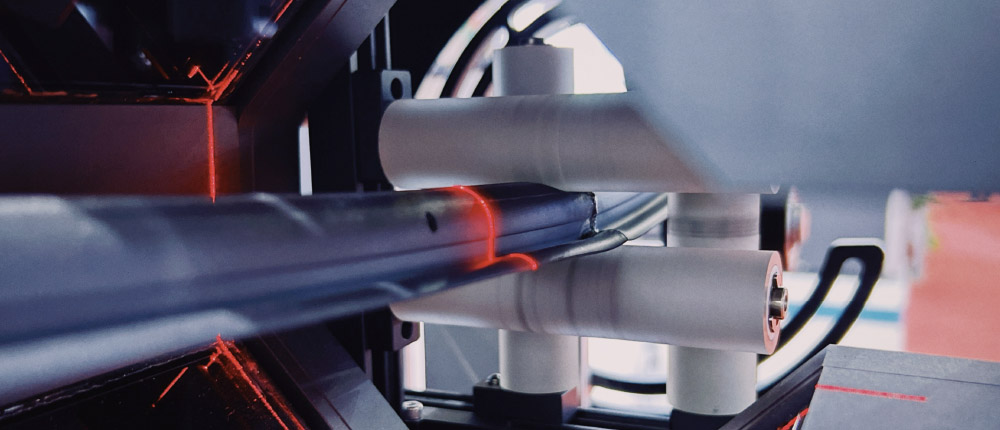

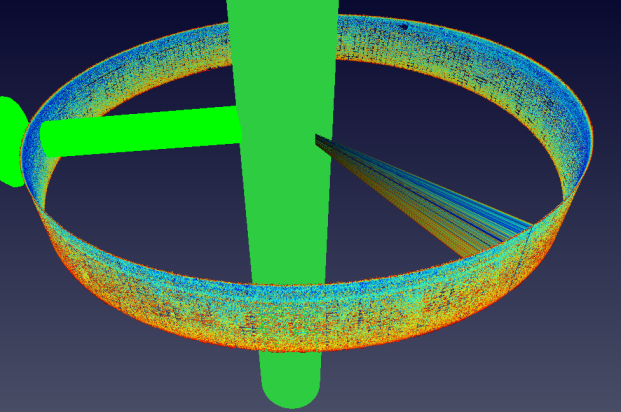

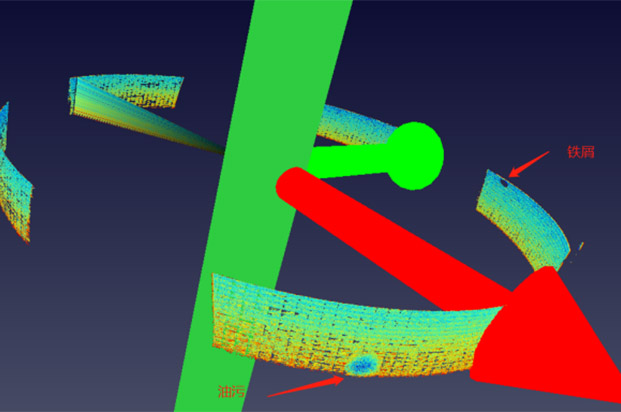

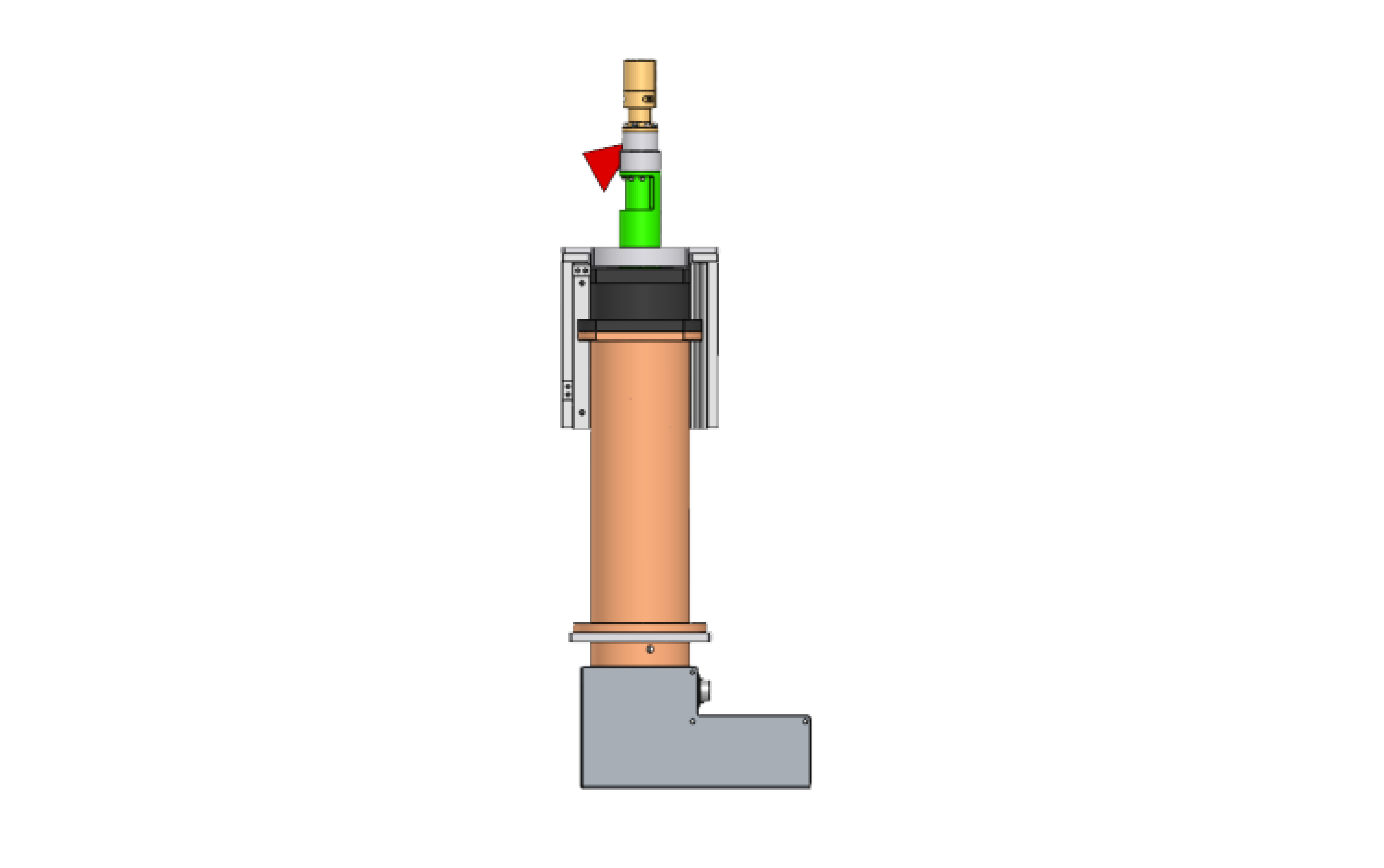

Based on the principle of laser triangulation measurement, a in-house developed high-speed 3D camera, combined with a line laser, enables fast, non-destructive, high-precision, and comprehensive online inspection of the hub's center hole diameter and width. This approach effectively monitors the actual machining of the hub's center hole by the cutting tools in the machining center during production, significantly improving inspection efficiency while greatly reducing manual inspection costs.

Follow Us

Follow Us